Table of Contents

Is Wood-Cutting Possible With a CNC Machine?

Absolutely, these machines are designed to work with all kinds of wood and can be positioned anywhere from the furniture industry to cabinetry and even in artistic woodworks modern day. While employing a CNC Machine for wood cutting, there are key features that need to be remembered:

- Precision: Carving of the CNC machine is done with really accurate measurements.

- Speed: Compared to manual woodworkers, CNC machines are faster, and so production promotes ease in productivity.

- Consistency: Shapes and structures can be replicated easily without any change.

- Complexity: Difficult and more detailed patterns can be done.

It is critical to choose the right wood and cutting mechanism in order to achieve successful results. Softwoods such as pine and spruce are easier to shave, on the other hand, oak and ceradian cherry are softer and need stronger mechanisms.

Best CNC Software for Cutting Wood

Choosing the appropriate CNC software is crucial for devising the design and generating a suitable tool path for cutting wood. These are some of the options available:

- Fusion 360 – Perfect for complex woodworking projects due to its 3D modeling and CAM integration features.

- Vectric Aspire – A simple yet effective program for creating wood art and carvings.

- SolidWorks – The best fit for professional mechanical woodworking practices.

- AutoCAD – Useful for highly accurate 2D or 3D models of wood designs.

- Carbide Create – Suitable for novices and small woodworking enterprises.

All software listed has its merits, based on the user’s level of experience and the complexity of the project.

best CNC Models for Woodworking

Custom CNC machines from certain brands enable easy operation, outstanding precision and finish, along with reliable performance, making them ideal for woodworking. These are the brands you want to keep in mind for woodworking:

- ShopBot – A favorite among hobbyists and small companies.

- BobsCNC – Great for beginners who are looking for decent pricing.

- Tormach – Suitable for low-scale production and design testing.

- Axiom Precision – Professional grade machines.

- Laguna Tools – Offers the best premium CNC woodworking machines.

These brands have various models that fit different budget ranges along with meeting specific project needs.

Selective Characteristics of CNC Wood Cutting

Different distinct processes are performed in a particular order to complete CNC wood cutting. The following processes are executed distinctly:

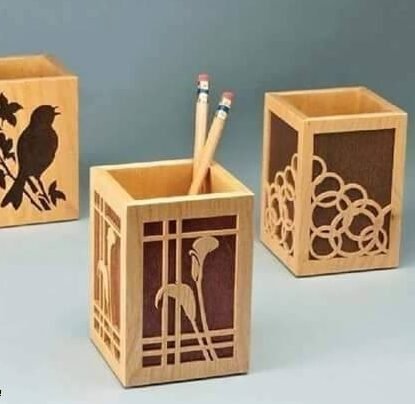

- 3D Relief Carving – This is used for detailed decorative artwork on wood panels.

- Pocketing – This process eyes on removing larger areas of wood.

- V-Carving – With the help of a V-shaped sculpting instrument, V-Carving engraves sharp and detailed artwork.

- Profile Cutting – This process involves cutting patterns or shapes out of wooden sheets.

- Inlay Work – This process involves placing other materials into wood creating a different appearance.

- Joint Cutting – Enables the making of finger and dovetail joints for woodworks.

These processes increase the effectiveness of CNC machines in the trimming of wood.

Conclusion

Amateurs or seasoned professionals looking to achieve precision and efficiency have CNC machines at their service. With knowledge of different cutting processes, users can get maximal results out of their wood cutting machines. However, their performance greatly relies on the machining software and CNC recognized brand selected.

Visit GlobalStreek.com for more tips and insights.

Leave A Comment