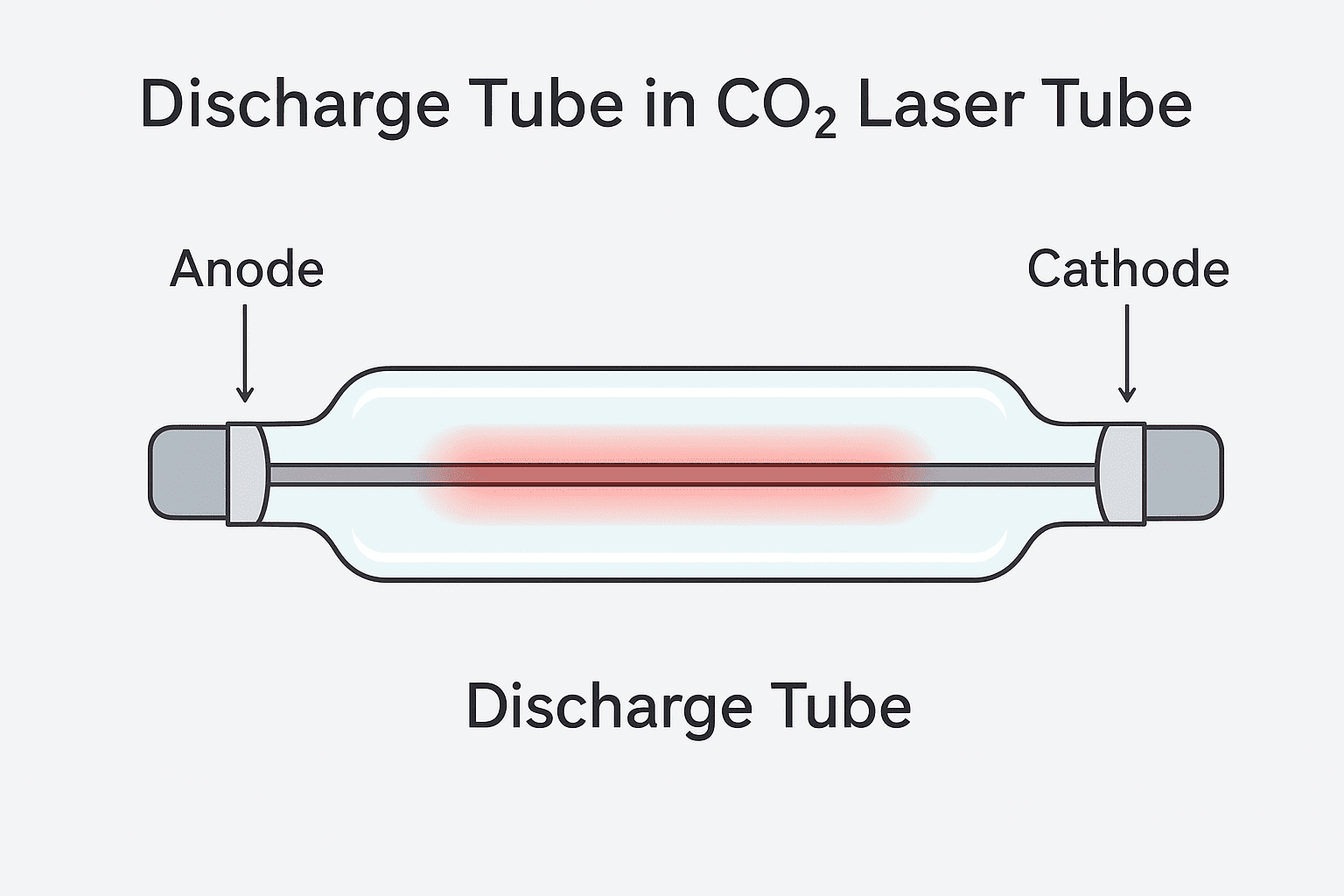

Discharge Tube in CO₂ Laser Tube

The Discharge Tube is one of the most essential parts of a CO₂ laser tube, playing a central role in the generation of laser energy. Without it, the electrical excitation and gas ionization process required to create the laser beam would not be possible. It acts as the core chamber where the electrical discharge interacts with the laser medium (a gas mixture of carbon dioxide, nitrogen, helium, and sometimes hydrogen or xenon) to produce coherent laser light.

What is a Discharge Tube?

The discharge tube is a long, sealed, cylindrical glass tube that contains the laser gas mixture. It is where the high-voltage electrical current passes between the anode and cathode terminals. This current excites the gas molecules, causing them to release photons. These photons are amplified inside the resonator to form the powerful, focused laser beam used in cutting, engraving, and marking applications.

Main Functions of the Discharge Tube

Containment of Laser Gas Mixture – The discharge tube is filled with a mixture of CO₂, N₂, and He gases in precise proportions.

Ionization of Gases – When voltage is applied, the discharge tube provides the space where the gases ionize and reach an excited energy state.

Photon Emission – Excited CO₂ molecules release infrared photons (at 10.6 µm wavelength), which form the basis of the CO₂ laser beam.

Channel for Laser Path – The discharge tube acts as the central path through which the laser travels before being reflected and amplified by mirrors at both ends.

Stability and Cooling Support – The tube is often surrounded by a water jacket for cooling, as the ionization process generates significant heat.

How the Discharge Tube Works

- Electrical Excitation – When high voltage is applied across the anode and cathode, electrons collide with nitrogen and CO₂ molecules inside the discharge tube.

- Energy Transfer – Nitrogen molecules absorb energy first and transfer it to CO₂ molecules.

- Photon Emission – Excited CO₂ molecules drop back to a lower energy level, releasing infrared photons.

- Amplification – These photons bounce back and forth between mirrors located at both ends of the tube, creating a coherent laser beam.

- Output – The beam exits through a partially reflective output coupler, ready to be directed toward the material for cutting or engraving.

Features of a Discharge Tube

Material: Made of high-quality glass (commonly borosilicate) to withstand high temperatures and vacuum sealing.

Sealed Construction: Keeps the gas mixture pure and stable for consistent laser performance.

Water-Cooled: Usually surrounded by a cooling jacket to regulate temperature.

Durability: Designed to last thousands of operating hours, though lifespan depends on usage and power level.

Importance of the Discharge Tube

It is the core working chamber of a CO₂ laser tube.

Ensures efficient excitation of gases for stable laser output.

Directly affects laser power, beam quality, and lifespan.

A damaged or degraded discharge tube leads to reduced laser performance and eventually failure of the tube.

Leave A Comment