Anode Terminal in CO₂ Laser Tube

Introduction

The CO₂ laser tube is the most critical component of a laser cutting or engraving machine. Inside this glass tube, high-voltage electricity excites a gas mixture of carbon dioxide (CO₂), nitrogen (N₂), and helium (He) to generate a high-powered infrared laser beam. To achieve this, the tube requires two major electrical connections – the anode terminal and the cathode terminal. In this article, we will focus on the anode terminal, its role, functions, features, and working process in detail.

What is the Anode Terminal in a CO₂ Laser Tube?

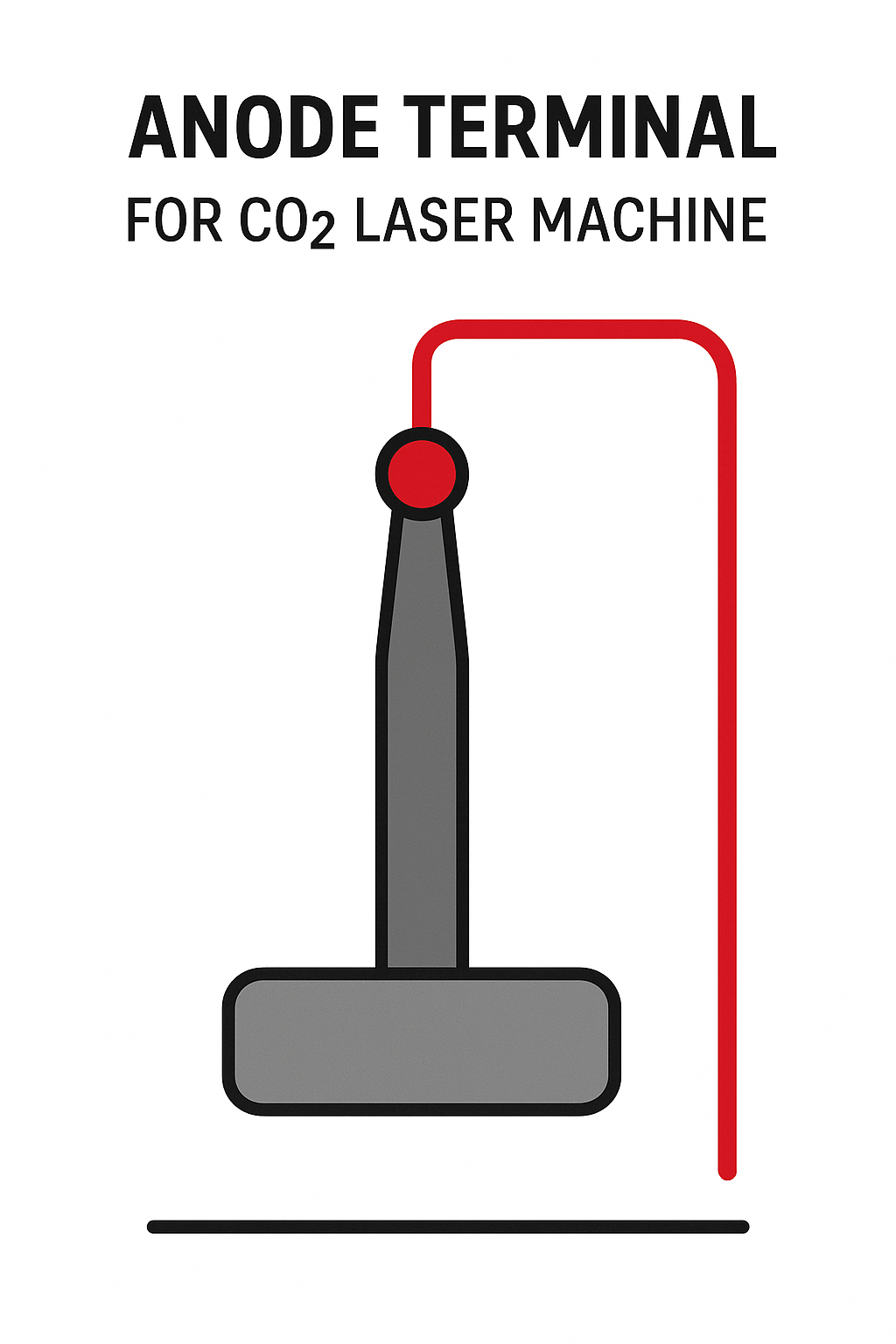

The anode terminal is the positive electrode of the CO₂ laser tube. It serves as the entry point for high-voltage electricity into the discharge tube, which excites the gas mixture and begins the process of laser generation.

It is usually located at one end of the CO₂ laser tube and covered with a high-voltage protective cap to ensure safety. The anode terminal is responsible for ensuring that the discharge process is stable, which directly affects the power, stability, and lifespan of the laser tube.

Where is the Anode Terminal Used?

The anode terminal is used in every CO₂ laser machine that relies on a laser tube for cutting or engraving. Some applications include:

- Laser Cutting Machines – For materials like wood, acrylic, MDF, plastic, and fabric.

- Laser Engraving Machines – For engraving patterns on glass, leather, and metal coatings.

- Industrial Laser Systems – Used in packaging, signage, furniture design, and decorative items.

- DIY Laser Machines – Smaller versions of CO₂ lasers also have anode terminals for hobbyist projects.

Without the anode terminal, a CO₂ laser tube cannot generate electricity inside the discharge tube, making it useless.

Features of the Anode Terminal

The anode terminal in a CO₂ laser tube has specific features designed for safety, stability, and performance:

- High-Voltage Capacity – Handles several kilovolts of electricity safely.

- Durable Material – Built from conductive metals that can withstand continuous electrical discharge.

- Protective Insulation – Equipped with a high-voltage protective cap to prevent shocks.

- Heat Resistance – Designed to tolerate heat generated during long working hours.

- Stable Connection – Provides a strong electrical link to avoid arcing or interruptions.

Main Work of the Anode Terminal

The main function of the anode terminal is to supply high-voltage electricity into the discharge tube. This electricity excites the gas molecules inside, which is the first and most important step in creating a powerful laser beam.

In simple words:

- Without the anode terminal, the laser tube cannot ignite the gas discharge.

- Without gas discharge, there will be no excited CO₂ molecules.

- Without excited CO₂ molecules, there will be no laser light output.

So, the anode terminal is the starting point of laser generation inside the tube.

How Does the Anode Terminal Work?

The working principle of the anode terminal can be explained in stages:

- Power Supply Connection – The high-voltage power supply connects to the anode terminal.

- Electric Discharge – When voltage is applied, current flows through the discharge tube towards the cathode terminal.

- Gas Excitation – The electrons collide with nitrogen and CO₂ molecules, exciting them into higher energy states.

- Photon Release – Excited CO₂ molecules release energy in the form of infrared photons.

- Laser Formation – These photons are amplified inside the tube by mirrors until a powerful laser beam is emitted.

In summary, the anode terminal initiates the chain reaction that ends with the emission of a strong, precise laser beam used for cutting and engraving.

Importance of the Anode Terminal in a Laser Tube

The anode terminal is important because:

- It ensures stable electric discharge.

- It maintains the power output of the laser tube.

- It prevents electrical arcing and damage to the tube.

- It directly impacts the lifespan of the CO₂ laser tube.

- It makes the laser machine safe by being covered with a high-voltage cap.

If the anode terminal fails, the entire laser tube will stop functioning.

FAQs About Anode Terminal in CO₂ Laser Tube

Q1: What is the function of the anode terminal?

The anode terminal supplies high-voltage electricity to excite the gases inside the CO₂ laser tube, which generates the laser beam.

Q2: Where is the anode terminal located?

The anode terminal is located at one end of the CO₂ laser tube, usually opposite the cathode terminal.

Q3: What voltage does the anode terminal carry?

Depending on the laser tube power rating (40W, 60W, 100W, etc.), the anode terminal typically handles several kilovolts of electricity.

Q4: How can I protect the anode terminal?

Always use the protective cap, keep it dry, and ensure proper water cooling in the machine to avoid overheating.

Q5: Can the anode terminal be repaired if damaged?

In most cases, damaged anode terminals require replacement of the entire laser tube, as repairs are not cost-effective.

Leave A Comment